Features: 11 Vacuum Tube Kt120(4) 6550(2) 12BH7 (4) ECC81 (2)

Design Regulated High Voltage Power Supplies

All Polyprolyene Film Capacitors

WBT Gold Plated Binding Post,

200amp Shielded Power Transformer, Torodial-Core

Related Power:90W/Channel continuous from 20Hz to 20kHz

THD:Less than 1% at all levels

Frequency response 5 Hz to 100kHz - 3db Input sensitivitiy:1,5 V for Rated Power Input Impedance:100 K ohms

Overall Negative Feedback 17dB Output Taps:16 ohms, 8 ohms, 4 ohms S/N Ratio:/HF-A More than 100dB

Output polarity: Non inverting

Power Consumption 600W Nominal

Mains Voltage 120V, 230V to 240V. Factory set for destination country only.

Mains Voltage Range:+/- 12%

Dimensions (mm)430W, 190H, 390D

Shipping weight:26kg

The CTA506 power plant is based on the KT120 power valves. These valves are a new variant of the legendary 6550 / KT88 power valves.

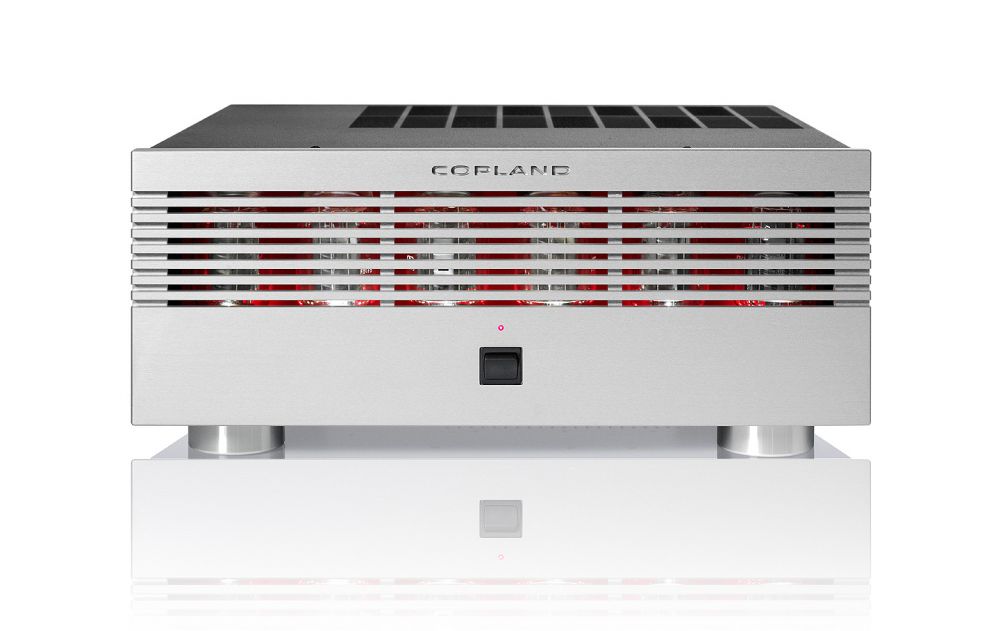

For more than half a century, these classic valves have been the foundation of numerous of high quality amplifiers and surely, they will continue to serve as one of the premium choices among manufactures of high-power valve amplifiers. However, nowadays KT120 is the most powerful dedicated audio tube in production. In comparison with the KT88, nearly 30% more power can be drawn from these impressive valves. With a plate dissipation rating of 60W, a pair of KT120 tubes in push-pull configuration can deliver nearly 200W of audio power. When used in circuit designs of more modest power outputs, the KT120 can deliver incredible quantity of headroom and dynamic without overloading. When output powers of more than 50W are going to be provided from a power amplifier, the input and driver circuits of the amplifier are confronted with a dramatic increase of current needed to supply the power devices of the amplifier. This is a reality regardless if the amplifier is based on bipolar transistors, Fets, or vacuum tubes technology, and no matter if single high power output devices are used for the design or if the amplifier employs multiple low power devices in a parallel configuration. Even though Fets-semiconductors and audio valves in theory are voltage controlled devices, these also require relatively low impedance driver circuitry with current capability, partly due to the increase of input capacities and partly due to the often neglected fact that also audio valves are drawing current through their input terminals. To prevent excessive loading of the amplifying stages of the amplifier, CTA506 employs efficient buffer circuitries as a method of partitioning the load from the amplifying valves. The buffers are current amplifiers with very low distortion and they do not amplify the signal, they only make it stronger. Another benefit from the use of buffer circuitries is that they allow low impedance DC-coupling between the driver and power valves of the CTA506. The CTA506 push pull output stages consists of a pair of marched KT120 in fixed ultra-linear configuration, giving the low distortion of triodes combined with the power of tetrode valves. A dedicated power supply for the input stages of the amplifier allows the massive central reservoir capacitors of more than 3000-microfarad to independently serve the output valves. In order to isolate power supply fluctuations of the power stage from entering the input and driver stages of the amplifier, the CTA506 employs active valve regulation by the use of two pieces type 6550 power valves, one of the valves dedicated to the driver stages only and the other regulating the amplifying stages with only a fraction of deviation from the voltage chosen to operate the valves in this application. The huge termionic power valves used in this construction are very attractive to look at; we have therefore decided to make them clearly visible by situating the valves behind lateral perforations on the front panel, thus creating what we consider to be a stunning design to mach the sonic virtues of this amplifier. The KT120 is an impressive power valve with a long plate structure and huge grid cooling. The Copland CTA506 is among the very first audio products to utilize this new generation of valves.