Frequency Response: 46–22,000 Hz ± 3dB

Horizontal Dispersion: 30 degrees

Vertical Dispersion: 26" (66cm) line source with a NAC™ enhanced sound field

Sensitivity: 89 dB/2.83 volts/meter

Impedance: 6 ohms, 1.1 at 20kHz

Crossover Frequency: 450 Hz

Components: Custom-wound audio transformer, air core coils

Weight: 31 lbs./channel (14.1 kg)

Dimensions (HxWxD):53" × 10.2" × 12.25" (135 × 25.9 × 31.1 cm)

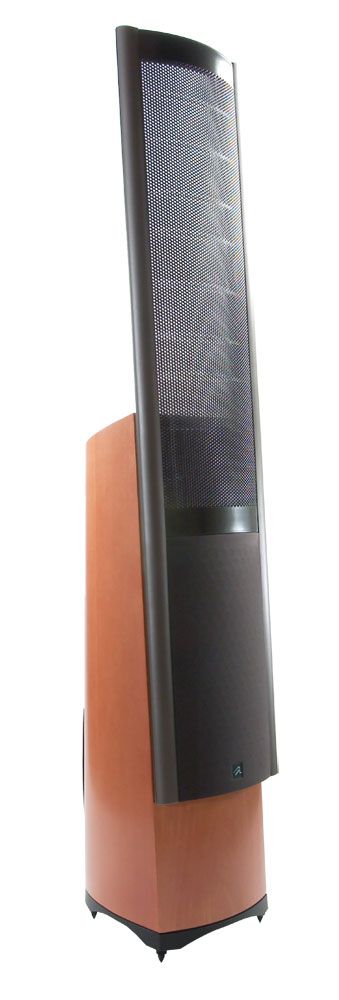

After 20 years committed to developing the world's most advanced and sophisticated loudspeakers, we knew our challenge was to build as much of that quality and performance as possible into a speaker that could be enjoyed by a much wider audience. It had to be pleasing to the eye as well as the ear, easy to install, and smaller and less expensive than our previous speakers. Yet it had to have the MartinLogan sound.

It's the kind of project that goes to the heart of the engineering process – and that drives innovation. Clarity inspired the development of our advanced CLS™ Generation 2 electrostatic transducer with MicroPerf™ stators and ClearSpar™ supports for superior performance from a small panel. Our design team also created NAC™ (Natural Ambience Compensation) technology, making it easier to enjoy full-spectrum sound throughout the listening area.

Even the cabinet is a radical departure, constructed of sonically welded constrained-layer laminates. Lightweight yet extremely rigid, it allows graceful, flowing lines in real wood materials. And Clarity is available in two handsome color palettes to enhance its appearance in any room. CLS™ Generation 2 Electrostatic Panel Innovative manufacturing techniques enabled MartinLogan to produce the original Curvilinear Line Source panels, the first wide-range electrostatic drivers to deliver good horizontal sound dispersion without sacrificing overall sound quality or reliability. CLS Generation 2 builds on that success with advanced diaphragm and stator technologies that significantly enhance speaker efficiency and dynamics.

Our new thin-film plasma-deposition process applies an improved conductive coating to the ultra-low-mass PET (polyethylene terathylate) diaphragm for superior adhesion and abrasion resistance, as well as a better impedance characteristic. MicroPerf™ stators expose more of the diaphragm surface, dramatically expanding effective radiating area without increasing panel size, while ClearSpar™ spacers help maintain their stiffness without impairing the signature transparent look of MartinLogan electrostats. Although stators are the elements of an electrostatic driver that are supposed to stand still, they carry the audio signals that do the work of propelling the diaphragm back and forth to move air and produce sound. Because the stators sandwich the diaphragm between them, they must be perforated to allow sound to pass through. Yet they must also be rigid enough to remain absolutely stationary despite the strong electrostatic forces pushing and pulling at them during operation.